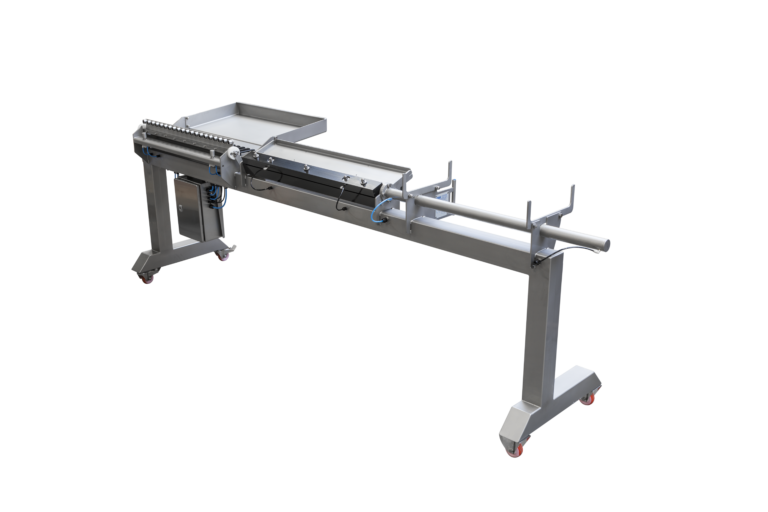

EAL MOD. ST915 AND MACKEREL MOD. ST916 SPEARING

The ST915 eel spearing machine facilitates the task of spearing eels onto a rod for subsequent smoking, considerably speeding up the process and ensuring greater safety. This device drives a rod through the eye area of the cultured eels (weighing 100 to 250 grams) and places them at an optimal distance from each other for the smoking process. Pre-formed trays allow the operator to manually feed the machine to pneumatically process approximately 20 eels per minute. By pressing two buttons simultaneously, the operator's hands cannot get near the system, as this activates a guard and pushes the bar. When the pusher system retracts, the machine is loaded with a new bar for the next batch, allowing the cycle to be repeated.

This device can be used to process:

- Fresh, farmed and gutted eel from 100 to 250 grams, with head

- Wild eel under strict conditions

Similar to the ST915, the mackerel model ST916 also facilitates the task of placing farmed mackerel (300-500 grams) on a smoking rod, making the job faster and safer. Pre-formed trays allow the operator to manually feed the spearing machine to pneumatically process approximately 14 mackerel per minute.

It can be used to process:

- Fresh, farmed and gutted mackerel from 300 to 500 grams with head

Both machines share the same features:

- Automatic re-loading system

- No extra adjustment needed in given range

- Optimal spacing for the smoking process

- Spear goes through eyes, not damaging the meat

- High speed

- Easy and manual loading: pre-formed feeding trays

- 100% pneumatic, no electricity needed

- Medium and professional processors

- Consistent