Desalting and washing hams: sustainability and efficiency

September 2, 2024

At Industries FAC SL, we pride ourselves on being at the forefront of innovation in the food industry. Our commitment to sustainability and efficiency has led us to develop, among other things, a ham desalting and washing line that not only guarantees the quality of the product, but also minimises the environmental impact through significantly reduced water consumption.

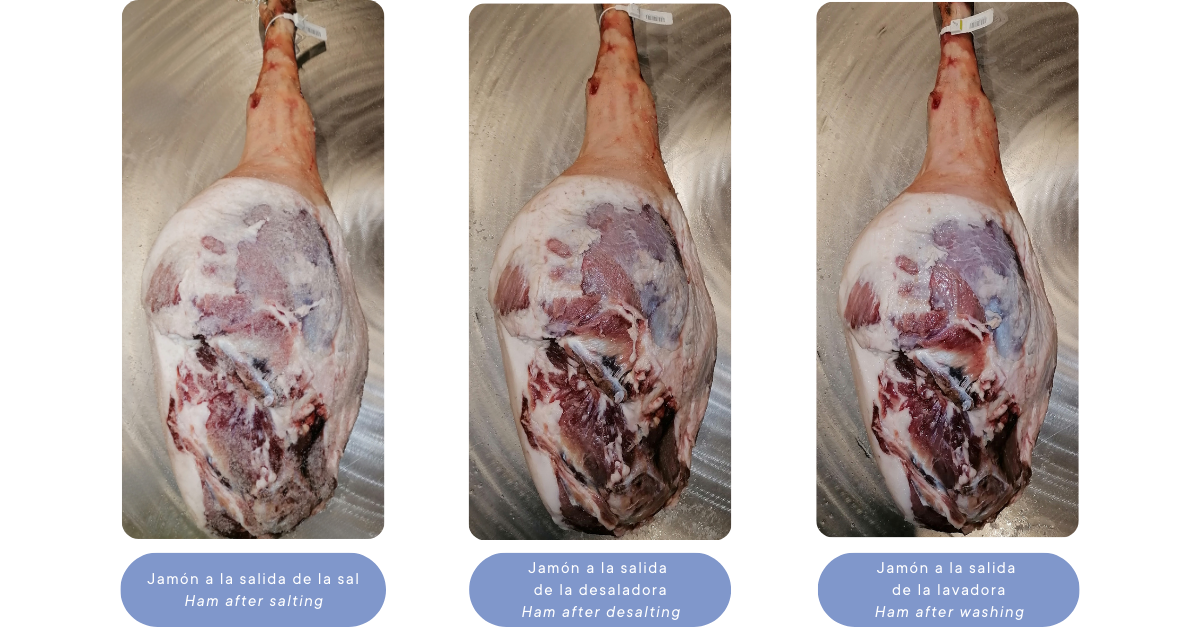

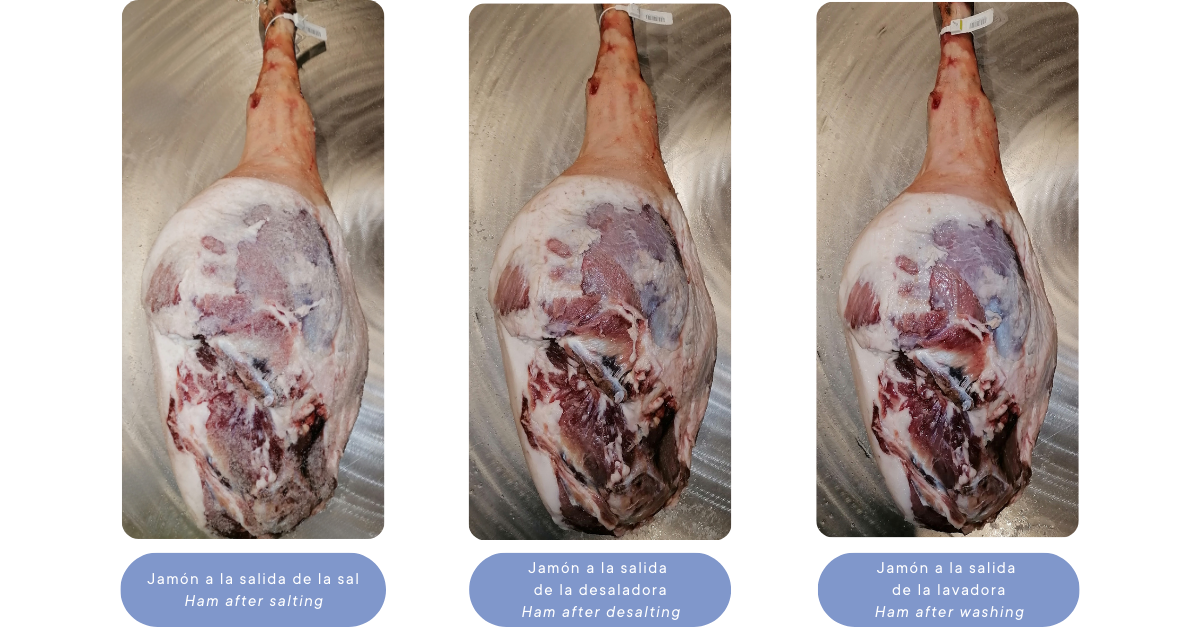

The challenge of desalting and washing hams

The desalting and washing process is a crucial stage in the production of cured hams and shoulders. During this process, salt excess is removed to achieve the ideal flavour and texture, and the ham is cleaned to remove any residue that may have built up during curing. Traditionally, this process consumes large amounts of water, which is not only costly, but also represents an environmental challenge in a world where water resources are increasingly limited.

Our solution: low water consumption technology

In response to these challenges, Industries FAC SL has developed the desalting and washing line consisting of two machines connected in line: the DSA-17SA desalter , which recovers dry salt by blowing high-pressure air, and the MINICON washer , which uses clean water without recirculating it, consuming less than 1.5 litres of water for each ham or shoulder. In addition, depending on the specific needs of each client, these machines can be purchased separately, thus allowing the desalter to be combined with other models of washers.

Benefits for the environment and industry

The benefits of our line are multiple:

1. Reduction and reuse of salt with the DSA-17SA desalting machine: by removing the adhered salt using a dry air pressure system, the salt that is currently discarded with the washing water can be reduced by up to 80% and reused for the salting process.

2. Water saving with the MINICON washer: as it has a high pressure system with volumetric control, the amount of clean water required for washing is about 1.5 L per piece, reducing consumption and drastically reducing the amount of waste water from washing.

3. Product quality: despite the lower water consumption, our line ensures that each ham is desalted and washed perfectly and evenly, maintaining the flavour and texture that consumers expect.

4. Reduced operating costs: less water and salt used means lower costs in terms of water supply and treatment, which is an important advantage for production companies.

5. Commitment to sustainability: 4. Reduced operating costs: less water and salt used means lower costs in terms of water supply and treatment, which is an important advantage for production companies.

Industries FAC, leading the change towards a more sustainable future

At Industries FAC, we believe that innovation and sustainability go hand in hand these days. We are committed to continuing to develop solutions that benefit both our customers and the environment. With our low water consumption ham desalting and washing line, we are proving that it is possible to produce high quality food while taking care of our planet.

I want to be updated and receive news, tips and products from FAC Food Technology.

savings, quality, desalination plant, efficiency, Indústries FAC, cured ham, washing machine, reuse, sustainability